Pouring a coat of slip onto the body of a leather-hard vessel, potter’s workshop in Berneck, Canton of St. Gallen.

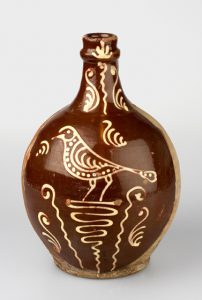

The coat of red slip, the white slip trailing and the glaze, which only partially covers the red slip, are all clearly visible.

Slip coating: a slurry of liquefied white or red-firing clay of varying thickness is used to fully or partially cover the unfired vessel body (greenware). The slip can be poured onto the vessel using a ladle or spoon, or the vessel can be dipped in the slip. The slip used in slip-coating can be dyed black, blue or green using metal oxides or it can be mixed with colour pigments, i.e. iron manganese particles (see speckled decoration). White or coloured slips are also used to add decorative patterns to earthenware using a brush or slip trailer. Slip coating is usually, but not always, covered with glaze.

A coat of white slip beneath green glaze.

In Swiss earthenware production, the first coats of slip were white in colour and applied to one side only (from the second half of the 14th century onwards), followed later by coats of red slip (prior to 1500).

Slip coating on both sides of the vessel (inside and out) became popular from the late 17th century, while coats of black slip only began to be used from c. 1780 (Heimberg-type pottery). Orange-beige slip coating, which was difficult to distinguish from the actual body of the vessel, was more frequently used from around 1800/1820. Coats of ultramarine blue slip were only used from the late 19th century and bright yellow-green slip coating did not appear until after 1880/1900.

Translation Sandy Haemmerle

German: Anguss, Beguss, Grundengobe

French: engobe, engobe de fond